Starting a new business in today’s ever-evolving market can be really daunting – especially if it includes the manufacturing of complex metal parts. Computer Numerical Control (CNC) Machine Shops help medium to large organization develop their complex components with the highest precision.

It is not compulsory for an organization to use a CNC Machine Shop only if they need technical components or metal parts manufactured. Look around you, most things you see include metal parts and components. If you’re looking forward to launching your new product relating to a metal part, you might want to mass produce several metal parts or components. This is where CNC Machine Shops come in handy.

But the question arises, what’s so special about CNC Machine Shops? How can they mass produce complex parts with utmost precision and ease? Is it practical to rely on a CNC Machine Shop? Well, follow this post and learn more about how it works at a CNC Machine Shop.

CNC Machine Shops Make the Impossible Possible

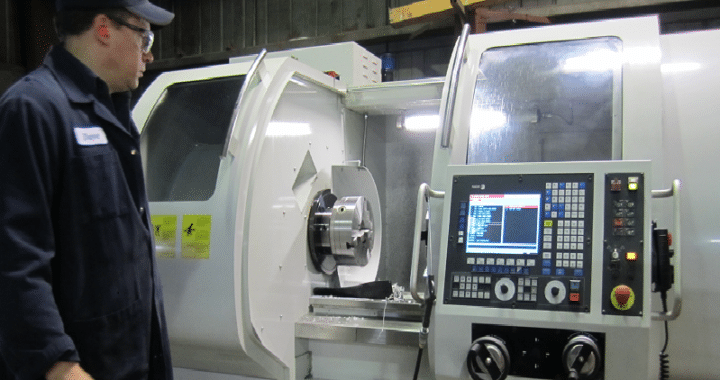

CNC Machine Shops aids in manufacturing complex components with utmost quality, precision, and high-grade equipment. An ideal CNC Machine Shop consists of a team of highly skilled machinists with enough experience to combat any to every manufacturing process and produce parts with tolerance range between 1-100 micron accuracy. Sounds fair enough?

The CNC Machining process can be applied to different materials including metals, plastics, glass, foam, wood, and other composites – molding them to something useful at your place. So, how do the experts at CNC Machine Shops make it possible to mass produce parts with high quality and precision?

Technically, CNC Machining is a computerized manufacturing process that manipulates high-grade machines and cutting tools to shape, resize, and mold materials into custom-designed parts. Though the CNC Machining process comes with several features and capabilities, the core principle remains the same all of them. The machining process at a CNC Machine Shop is divided into 4 stages, they are

- Finalizing and Designing the CAD Model of Project

- Implement the CAD Model to the CNC Computer Program

- Programming the CNC Machine to produce custom parts

- Execute the manufacturing process

Follow this post and learn more about how a CNC machine shop can mass produce parts in a timely manner.

CAD Model Design – How Does it Work?

Before getting started with the manufacturing process, the work starts with the development of a 2D vector drawing. What kind of parts or components are required? At this time, the buyer talks with the CAD expert at the CNC Machine Shop and gives an overview of the required parts. Buyers can also consult a third-party CAD/CAM Design Service Company to finalize the design and then contact the CNC Machine Shop.

The CAD Software allows the designers to render the desired parts with mandatory specifications i.e. exact geometries, dimensions, texture, and other specifications. After the CAD design is created, it is exported into the CNC Machine supported file and sent in for the conversion.

Implementing CAD Model to the CNC Computer Program

After creating the CAD design, the model is then un through a CNC program – generally called Computer-Aided Manufacturing Software. This allows geometrical extraction of the CAD design to implement in the CNC machine and manipulate the cutting tools to produce custom-designed parts.

Modern CNC Machines use multiple programming languages including M-Code and D-Code. Out of the languages, G-Code aids in controlling the cutting tools of CNC Machine and direct them to a particular location across the materials. On the other hand, M-Code aids in controlling the auxiliary functions of the CNC machine.

Setting Up the CNC Machine

The machinists must set up the CNC Machine before running the CNC program on the machine. The set up includes fitting the workpieces in the CNC machine vises, spindles, or other withholding tools. Some other required tooling like drill bits, holders, and proper end mills are also attached per the part type. After setting up the machine thoroughly, it is ready to run the CNC program and manufacture products right away.

Execute the Manufacturing Process

As discussed earlier, the CNC program acts as a set of instruction to the CNC machine, it is the foundation of operating the machine’s tools by use of an integrated computer – also known the controller. The machine’s integrated computer operates, manipulate, and command the machine tooling.

To begin manufacturing, the CNC program is initiated to execute the machine operations and produce custom-designed products or parts. Note that in case a company needs CNC machining for a long time, it can invest in the in-house CNC machining and obtain its own CNC equipment.

Final Verdict

In a nutshell, the mentioned 4 parts of the CNC machining makes it possible to mass produce high-quality products with the desired tolerance. This multi-staged process and its credibility are directly proportional to the shop’s and its machinists’ potential. Thus, if you’re looking to use a CNC Machine Shop anytime soon, make sure to conduct thorough research before choosing the right CNC Shop for your project.

Also, there are many companies investing in the CNC machining to conduct in-house manufacturing of their products for the sake of reduced scrap, productivity, and enhanced quality measures

Learn more about CNC machining and its applications here. And in case of further questions, feel free to leave a reply below.