With the robust technological growth and advancement, it is now possible to complete a task in a short period, as compared to the time when there were no precision machine shops. One of the main reasons why majority of the companies usually prefer a precision machine shop is mainly because it saves time and money.

Manufacturing process have become quite easy mainly because there are several precise machineries developed. The main reason of developing such machineries was to produce cost-efficient products and save time.

The question that usually arises is; what made this possible? After several years of research and experiment, numerous companies originated which produced different precision machines, which help in the manufacturing of different products. One of the best precision Dallas Machine Shops among all the rest is Bates Machine and Mfg.

Bates provides several services like Laser cutting, CNC punching, forming, CNC machining, help with product design. In short, these are all of those tasks that take a huge of time and cost great deal of money. This is the main reason why precision machine shops like Bates Machine and Mfg. started manufacturing products which made these tasks easier than before.

One of the main reason why precision machinery was produced was mainly to save time. At times, it is not only a single part, but it is actually the whole process that is creating the difference, mainly when it comes to satisfy the customer and meet the deadlines.

For almost any company, the first and by far the most important thing is to satisfy the customer, which is only possible if the deadlines are met punctually. With the help of precision CNC machines, it is now possible to manufacture products and run processes in a short period that ultimately save a lot of time and money.

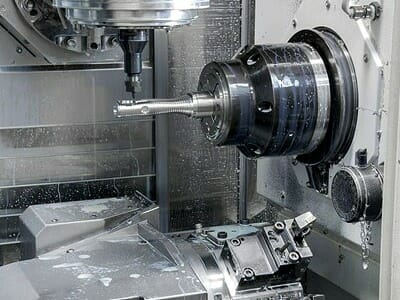

Other than just saving the time, CNC machines also help in producing products more efficiently as compared to the human labor. Tons of products can be manufactured in the short span of time, more accurately and precisely. Apart from this, human labor requires more effort and consume more time as well.

The second factor for using the precision of a CNC machine is a better is because it is cost-efficient and saves money. Paying of the labor, recruiting the staff and hiring professionals usually cost more than installing the precise and heavy machineries in order to perform heavy-duty tasks. For instance, laser cutting, CNC punching, forming, CNC machining and powder coating can be made easier with the help of the machines rather than hiring the staff and labour to perform such duties.

Apart from this, machines also help in manufacturing the products and operating the processes with more precision and accuracy, as compared to the manual method. In order to run businesses like farming, ranching, agricultural and industrial processes it is necessary to use precision machineries in order to make the processes faster and swifter.

Companies like Bates Machine and Mfg. are currently working to produce and develop several such processes to make the heavy-duty tasks easier and a lot more convenient. With the help of the precise CNC machine, it is now possible to operate such tasks without the consumption of long hours. Moreover, with the help of the precision machine shops the tasks have become cost efficient as well.

Newer CNC Machines have made tasks a lot easier, faster and convenient. For more informative articles, stay connected.