Why Small Businesses and Machine Shops Should Consider CNC Production Outsourcing

Running a small business or operating a home-based machine shop requires juggling high-quality production, costs, and deadlines, often with limited resources. This is especially true when it comes to CNC machining, where access to advanced equipment and skilled labor can be financially challenging. For businesses in this situation, CNC production outsourcing offers a cost-effective and efficient solution to meet demands without sacrificing quality.

This blog will explore the benefits of CNC production outsourcing, the flexibility and cost advantages it brings, common materials used in outsourced CNC machining, and key points to keep in mind when selecting a CNC outsourcing partner.

What Is CNC Production Outsourcing?

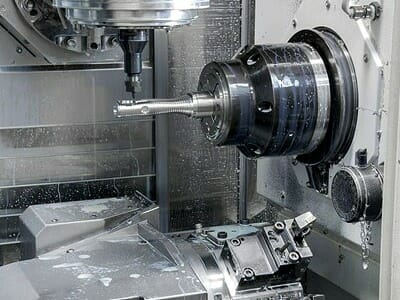

CNC (Computer Numerical Control) production outsourcing refers to delegating part or all of a product’s production to an external CNC machining service provider. Instead of investing in expensive equipment, hiring new staff, or expanding your facility, businesses can work with professional machining shops that already have the expertise, machinery, and workforce to deliver high-quality products.

For small businesses and home-based machine shops, outsourcing can level the playing field, allowing them to compete with larger manufacturers by cutting costs and improving efficiency while maintaining customer satisfaction.

Key Benefits of CNC Production Outsourcing

Outsourcing CNC machining work brings a range of benefits for growing businesses. Here’s why it might be the perfect choice for your operations.

1. Significant Cost Savings

CNC equipment is expensive, and the financial burden of purchasing machinery, maintaining it, and hiring staff can quickly add up. Outsourcing removes the need for these investments. An external shop already has the state-of-the-art equipment, skilled technicians, and overhead covered.

Outsourcing also eliminates recurring costs such as:

- Equipment depreciation

- Maintenance and repairs

- Rent and utilities for extra space

- Employee salaries, benefits, and training programs

By leaning on an external CNC service provider, you can allocate your financial resources toward other growth-oriented areas of your business.

2. Scalability and Flexibility

Markets fluctuate, and so does demand. Outsourcing allows you to quickly adjust your production capacity based on seasonal or sudden industry demands. Whether you need to produce a single prototype or a full production run, outsourcing partners can scale their services to match your requirements.

This flexibility ensures that you won’t need to invest in costly new equipment or additional staff when experiencing a production spike. Instead, you can meet demand seamlessly and stay ahead of your competition.

3. Access to Advanced Machinery and Expertise

Small businesses and home machine shops often face limitations when it comes to access to advanced CNC machines and highly skilled technicians. Outsourcing solves this challenge by connecting you to service providers who use cutting-edge technology and are experts in machining processes.

For instance, outsourcing to a provider like Bates Machine & Mfg. in Texas can give you access to advanced machines, such as:

- Haas VF2SSYT Mill

- Leadwell T-7 Lathe

- Epilog Helix Laser Engraver

- Mazak Lathe

With the right partner, your products will reflect a level of precision and quality that might otherwise be unattainable.

4. Faster Turnaround Times

Professional CNC machining shops are equipped with the resources to complete projects quickly. Their streamlined workflows, advanced machinery, and skilled workforce ensure efficient production timelines. Whether you’re fulfilling a bulk order or rushing to meet a launch date, outsourcing can help you deliver faster without compromising quality.

5. Higher Quality Products

Established CNC service providers follow strict quality control practices to ensure that every product meets specifications. Outsourcing guarantees superior-quality parts and components, enhancing your product’s reputation and keeping customers satisfied.

6. Focus on Core Competencies

When you outsource your CNC machining work, you free up time and resources to focus on the strengths of your business, whether it’s product design, marketing, or customer relationships. This enables small business owners and machine shop operators to dedicate their energy to driving growth rather than managing complex production challenges.

Common Materials Used in Outsourced CNC Machining

Choosing the right material for your project is crucial. Many CNC machining providers work with a variety of materials to meet diverse manufacturing needs, including:

- Metals: Aluminum (6061-T6, 7075), brass, copper, stainless steel (304, 316), and tool steel.

- Plastics: ABS, acrylic, Delrin, HDPE, nylon, polycarbonate, and Teflon.

Understanding the materials the service provider offers can help you match their capabilities to your project needs.

How to Choose the Right CNC Production Outsourcing Partner

Outsourcing production to a CNC machining service is a critical decision that can make or break your project’s success. Here are some tips for selecting the right partner:

1. Evaluate Their Experience

Look for companies with a proven track record in CNC machining. Check reviews, testimonials, and client references to assess their expertise. Providers like Bates Machine & Mfg., which specialize in production machining outsourcing, offer reassurance through years of experience and a long list of satisfied clients.

2. Consider Equipment and Technology

Ensure the provider has up-to-date CNC machines, along with support for high-tech processes like laser engraving and automated bandsaw cutting. This ensures precision, quality, and efficiency in production.

3. Verify Material Compatibility

Different projects require different materials. Make sure the provider can work with the metals or plastics you need for your project.

4. Request a Sample or Prototype

Before committing to a full-scale partnership, request a prototype or sample run. This allows you to evaluate the quality, precision, and attention to detail of their work.

5. Check Scalability and Flexibility

Partnering with a provider that can scale production up or down based on your business needs gives you long-term reliability and peace of mind.

6. Compare Costs

While cost savings are a big advantage of outsourcing, ensure you’re receiving value for the price. Request detailed quotes to evaluate what’s included in the service, from setup costs to quality inspections.

Maximize Your Business Potential with CNC Production Outsourcing

Outsourcing CNC machining is more than a cost-cutting strategy—it’s a business investment that allows you to focus on growth, improve product quality, and achieve faster time-to-market. Whether you’re running a small business or a home-based machine shop, partnering with a reliable CNC machining provider like Bates Machine & Mfg. can help you meet customer expectations while staying competitive.

If you’re ready to explore your CNC production outsourcing options, contact an expert to learn how it can benefit your business. Take the first step toward streamlined, high-quality production today.