Why Precision Machining Is Important to a CNC Machine Shop

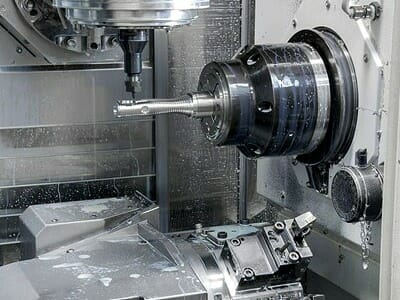

CNC cutting machines, like routers and mills, create products by making cuts into the desired workpiece across several axes. These machines at Bates MAchine and Mfg. in Farmersville,Texas work off of computer design programs to create uniform, accurate products.

Unlike manual machining, these machines can run 24 hours a day. They also require fewer operators, reducing labor costs and increasing production scalability.

Accuracy

One of the most important aspects of a CNC machine is its accuracy. Whether you need to cut a metal piece or wood, the accuracy of the  machine will determine the quality of the finished product. A high level of accuracy saves time by preventing the need for rework. This will help your project finish on schedule and reduce costs.

machine will determine the quality of the finished product. A high level of accuracy saves time by preventing the need for rework. This will help your project finish on schedule and reduce costs.

The accuracy of a CNC machine depends on several factors, including its design, material and production volume. It is also affected by the condition of the machine. A well-maintained machine with the right tooling will produce accurate parts that are repeatable. A machine with higher accuracy is better suited for producing parts with tight tolerances.

To improve machining accuracy, you should use add-ons like locators and touch probes. These devices are able to measure a machined part’s location in less than a minute. This will allow you to take more precise cuts, which will improve accuracy.

Design Retention

Machined parts are often extremely precise and must meet rigorous tolerances that the human eye can’t even detect. This is especially true for medical precision parts, which must be fabricated to exacting standards to ensure the safety of patients and employees.

While manual machining is limited by the number of skilled workers available, CNC milling machines can operate 24 hours a day. This means that fewer skilled workers are needed and production can be increased.

Additionally, a CNC machine can save prototype designs and re-use them for future production runs. This helps to streamline the manufacturing process and create uniform products.

Depending on the design of a particular piece, a CNC machine can be programmed to work in three or more axes. This allows the machine to work on complex shapes that would be difficult for a manual machinist to complete. This flexibility increases the number of orders a machine shop can fill and is beneficial for businesses that need quick turnaround times on prototypes or full-scale production.

Efficiency

The machining time of a cnc milling machine is influenced by the material type and its design. Hard metals require more time to process compared to softer materials like brass and aluminum. In addition, complex part designs and high tolerances can lead to machining delays.

To improve machining times, the choice of raw materials and the quality of CNC programs can be crucial. Selecting a material that is machinable and using a program that works with your machine’s software protocol will help cut the time it takes to produce a made-to-order product or prototype.

Unlike manual machining, CNC machines can operate 24 hours a day without human intervention. If a production change is needed, the operator can simply alter the computerized program to produce the new form. This flexibility enables shops to work on a wide range of projects, from small orders to large batches of identical parts and prototypes. It also means that fewer skilled engineers are required, which decreases operating costs and increases the scalability of production.

Flexibility

Manual machining requires skilled workers to operate it, and when those people take a break or are out sick, progress stops. However, CNC machines can run 24 hours a day. After an operator sets up the machine with the desired design, it can continue producing that design over and over again. This flexibility means that the machine can meet the demands of orders ranging from large batches of identical parts to individual prototypes.

Additionally, CNC machining is more scalable than traditional machining, and this is due to the fact that it uses a program to set up the desired piece rather than a skilled human operator. This reduces labor costs and increases production efficiencies. It also ensures that your shop is capable of keeping up with a rapidly evolving market. This makes cnc milling an invaluable tool for companies in industries like energy, aerospace, and automotive.