The Benefits of Working With a Dallas CNC Machine Shop

If you’re in the market for precision machined components, you’ve probably considered a Dallas CNC Machine Shop. These companies specialize in precision-machined components for various industries, including automotive, aerospace, and construction. With the help of a Dallas CNC Machine Shop, you’ll be able to make exact replicas of any part you need, whether it’s a new car, a tool for a construction project, or a precision-machined component for an industrial application.

Lessons learned from working in a CNC machine shop

Before automation, part-production data was collected manually by employees logging hourly production numbers for each machine into a spreadsheet. Now, shop management can see exactly how much a machine can produce on any given day, and how much unattended production time each machine has over night. The shop can then compare actual production time with anticipated production time by checking machine-status codes. Some codes show idle time while waiting for materials, tooling, or operator attention.

spreadsheet. Now, shop management can see exactly how much a machine can produce on any given day, and how much unattended production time each machine has over night. The shop can then compare actual production time with anticipated production time by checking machine-status codes. Some codes show idle time while waiting for materials, tooling, or operator attention.

Learning to program a CNC machine involves learning the ins and outs of a machine’s control systems. During a CNC training course, you will learn how to program a machine using computer software. You will also learn about programming concepts and master the basic MasterCam system. This training program takes approximately 64 weeks. It also covers the basic principles of CNC operation. The program also includes learning to set up a CNC milling machine.

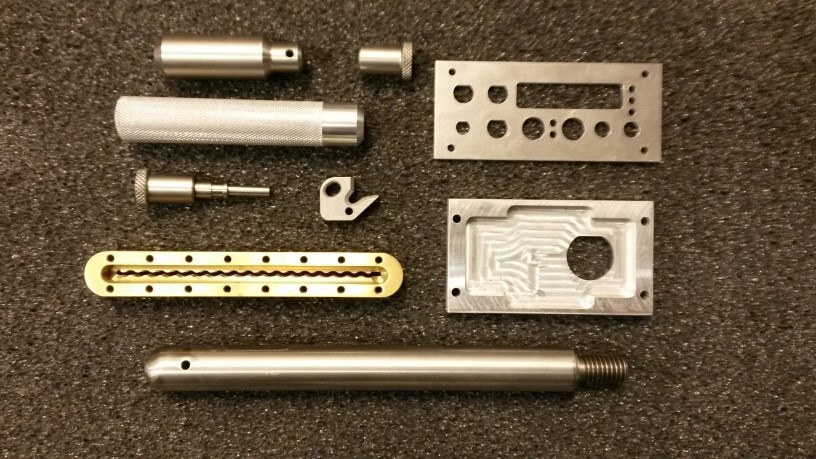

Equipment used in a CNC machine shop

A CNC machine shop in Dallas is well-equipped to produce a variety of parts. The following equipment is commonly used in such a shop:

Coordinate measuring machines measure the geometry of parts during the manufacturing process. They ensure that the machining process meets the original dimensional specifications. Coordinate measuring machines also ensure that the parts are made accurately. There are also different types of machines used for various manufacturing operations. These machines may be manual or equipped with CNC technology. They may also store raw materials or other materials that will be used for the parts. They may also contain a warehouse where finished products are stored.

A machine shop in Dallas should also be clean and have a clean environment. Dust and other debris should be cleaned regularly. Workers should avoid wearing flammable and loose-fitting clothes. In addition, they should wear safety glasses when operating machinery. It is important to remember that chips from the workpiece can seriously injure or even kill a person. Additionally, workers should not operate machinery while intoxicated or ill. Moreover, workers should always follow the instructions on their operator’s manual before operating a machine. It is also essential to understand where the switches are located to avoid any potential fire risks.

Quality control inspections performed by a CNC machine shop

If you are looking for a precision CNC machine shop in Dallas, Texas, you should choose one with a quality control inspector like Bates Machine and Mfg. Quality control inspections include final inspection, in-process inspection, and 1st piece acceptance. In addition to performing final inspections, the inspector will be responsible for overseeing the quality of the finished products. Some of the benefits of working at a quality CNC machine shop include health insurance, 401K match, and paid holidays.

A Dallas CNC machine shop that offers quality control inspections will follow a product’s life cycle. This lifecycle includes various stages including the ideation phase, design phase, feasibility study, analysis phase, and mass production. It is crucial to follow strict quality control inspections at each stage of the process to avoid producing substandard products. Additionally, CNC machines are ideal for rapid prototyping, as they are capable of producing prototypes with tight tolerances. These advantages come with the lowest risk of errors and minimal cost.

Location of a CNC machine shop

If you’re interested in owning a CNC machine shop in Dallas, Texas, consider acquiring one from a reputable source. Owens Industries, a leading manufacturer of precision machined parts, is located in the city. This Dallas CNC shop was established in 2013 and serves various manufacturers and industry entrepreneurs across the United States. QT Manufacturing specializes in producing custom injection molds, tight tolerance injection molded parts, and production CNC machining. Expert engineering services are provided and the company utilizes the latest CAD/CAM software.