The Benefits of a CNC Machine Shop

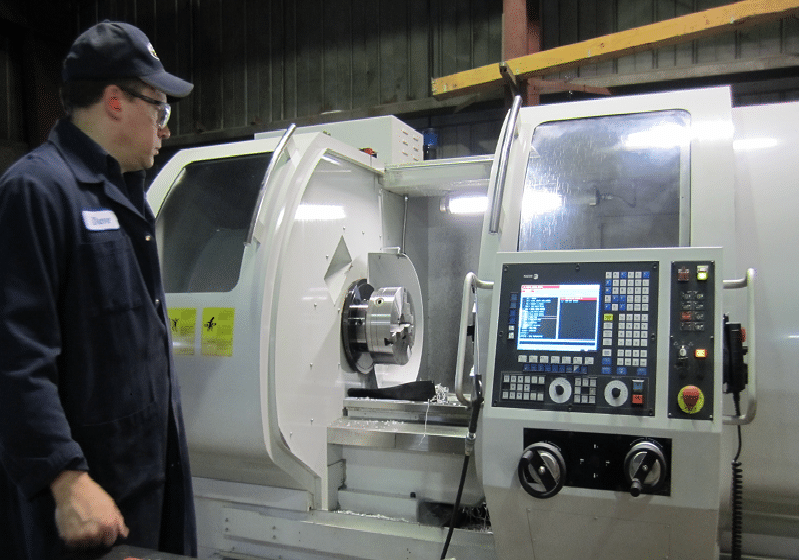

Machine shops are responsible for manufacturing parts in large quantities. They also provide other services. They use hand tools, power tools and measuring instruments to do their work.

The quality of these tools and equipment is crucial to a good job. They must be able to meet high-precision specifications. They must also have a fast turnaround time.

High Precision

High precision machining is an essential service for businesses that require high-quality products. This service produces parts with extremely precise measurements and tight tolerances, which helps companies avoid costly mistakes during production. It is also essential for ensuring that the final product meets quality standards and can be safely used by consumers.

precise measurements and tight tolerances, which helps companies avoid costly mistakes during production. It is also essential for ensuring that the final product meets quality standards and can be safely used by consumers.

When choosing a high-precision machine shop, it is important to consider the company’s technical expertise and their experience with your specific industry. The longer they have been in business, the more likely it is that they have encountered a variety of challenges and found solutions for them.

You should also ask about the average delivery times. A reliable machine shop will be honest about their capabilities and will not promise unrealistic turnaround times. In addition, they will provide regular updates and respond quickly to questions. Lastly, they should be able to offer a range of services to meet your unique needs. They should be able to perform 3 to 5-axis CNC milling, CNC turning and Swiss lathe machining.

Fast Turnaround Time

The best metal fabrication and CNC machine shops can handle a wide variety of jobs. They also offer quick turnaround times. This is important for customers, especially when they have strict deadlines. It allows them to save costs and avoid a lot of headaches.

Turnaround times are an essential part of the machining process. They determine how long it takes to finish the work and deliver it to the customer. They also help determine how efficient the operation is. In addition, they can help a business grow its revenue potential.

Some machine shops focus on building a steadfast relationship with their clients. They communicate with them through diverse media and proactively inform them of their order status. They are also committed to maintaining data privacy, particularly when it comes to proprietary designs. Some of them ask their customers to sign an NDA before they start working on a project. This ensures that your designs will not be shared with anyone else.

Customization

A CNC machine shop can provide businesses and product developers with a wide range of customization options to ensure their products are exactly what they want. This includes the ability to choose the materials used to produce parts, as well as the choice of finishing methods. This helps to reduce production costs and improve the quality of final products.

When choosing a machine shop, it is important to find one that can offer you competitive rates. However, it is also vital to consider the level of expertise and the quality of customer service that they offer. The best shop will have a high standard of both and will be quick to respond to any questions or concerns you may have.

Additionally, it is essential to select a machine shop that can maintain confidentiality and protect your intellectual property. This can be achieved by getting them to sign a Non-Disclosure Agreement before you share your design specifications with them.

Reliability

The most reliable machine shops will have a good track record. Moreover, they will communicate effectively with customers and provide updates at regular intervals. They will also be able to maintain confidentiality and protect customers’ intellectual property. They can do so by making their employees sign Non-Disclosure Agreements or letting them use digital mediums to check orders.

Using lean principles and design for manufacturability, these companies strive for enduring reliability. They also encourage their clients to visit the shop to build a relationship with the people they will work with. This face-to-face contact builds trust on both sides.

In addition, they practice sustainability and eco-friendliness in order to minimize their negative environmental impacts. They also have strict safety precautions and enforce them daily. For example, they ensure that swarf (chips) are removed daily and the machines are air-blown and wiped clean. They also make sure that the fire extinguishers are inspected regularly and that their employees wear appropriate personal protective equipment.