A large number of tasks are performed by the machine shop in industrial establishments. Those jobs which require high-quality machining techniques, including lathes, boring machines, roll milling machines, and conveyor belts, are part of the job description of a machine shop.

These tools are important for the oil field parts manufacturing industry. The oil field parts manufacturing industry is known for its complete range of products that consist of everything from automotive parts to aircraft engines.

This industry also employs a great deal of repair machinery. To provide precision and timely service to these clients, a machine shop has to be equipped with some of the best machines.

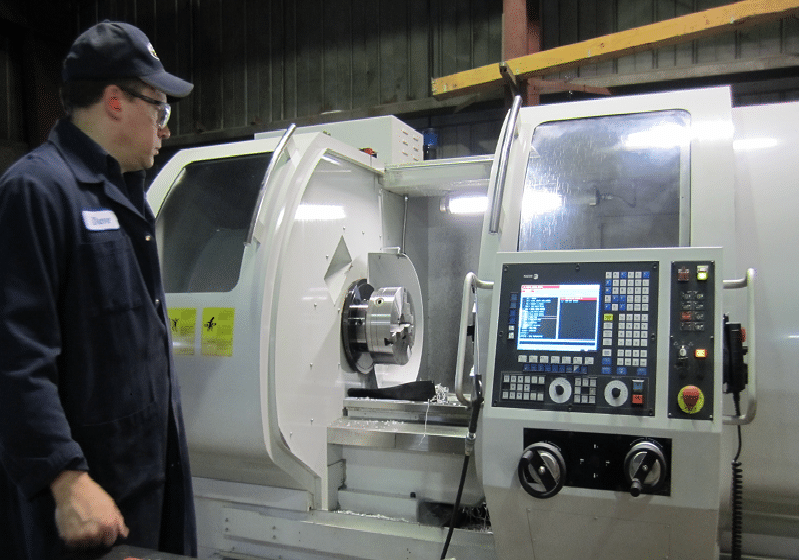

A local machine shop has to have the latest and most advanced machines available. It has to have the top-of-the-line machinery, most of  which is used on a daily basis. These machines are usually electric powered, and they run on a unique motor.

which is used on a daily basis. These machines are usually electric powered, and they run on a unique motor.

Manufacturers of these products are well-known for offering the best and most affordable prices for their products. In order to attract these customers, manufacturers invest heavily in advertising.

There are many sales literature and marketing campaigns, where these machines are advertised. The machinery manufacturers take advantage of this to advertise their machines, as well as other products. Other companies also advertise in magazines and newspapers.

Local machine shops are very useful for attracting customers to purchase products from their business. In some cases, customers visit these stores just to have a closer look at the machines in order to compare prices and features.

A machine shop that deals with oil field parts manufacturing is also known as an oil field parts shop. They operate out of a set of large buildings or sheds, and each is equipped with such essential tools as drilling machines, augers, and other equipment. Some of the equipment that is installed in the plant include diesel trucks, push belts, compressors, drive units, and feed rollers.

A machine shop in the oil field uses many types of steel drilling machines and other equipment. Among these are drilling, pinch sets, and drills with bow drills.

In addition to these machines, the oilfield parts manufacturing company may also use drilling machines, many of which are specially designed for the purpose of drilling holes in crude oil. These machines are powered by diesel engines, and the holes produced by the machines are intended to accommodate the oil.

Oilfield parts manufacturing is a business that provides a high volume of income. Because of this, a machine shop is an essential part of this industry.