Maintaining Accuracy in CNC Machining Shops

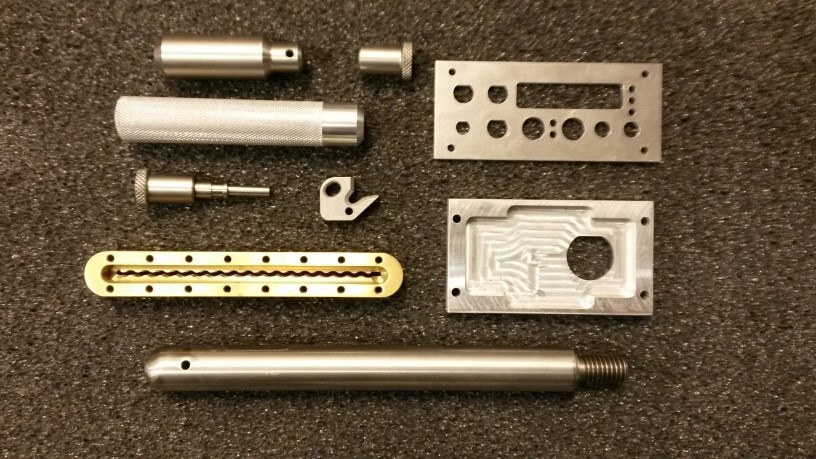

Family owned CNC machining shops, like Bates Machine & Mfg. in Farmersville, Texas must maintain accuracy in order to produce high-quality products. This involves maintaining a proper working environment and performing regular maintenance on the machines. It also means having a strong supply chain network that provides materials and components promptly.

Precision refers to the closeness of machined parts to their specified dimensions and tolerances. Accuracy, on the other hand, refers to the reliability of a measurement system.

Precision

A cnc machine shop is an ultra-modern manufacturing facility that uses computer numerical control (CNC) technology to produce precise and accurate metal products. It combines software and hardware to transform design specifications into coded instructions that can be read by the CNC machine. These instructions then direct the machine to shape and cut metal into various shapes. The precision of a cnc machine shop is determined by the quality of its equipment, personnel, and processes.

and accurate metal products. It combines software and hardware to transform design specifications into coded instructions that can be read by the CNC machine. These instructions then direct the machine to shape and cut metal into various shapes. The precision of a cnc machine shop is determined by the quality of its equipment, personnel, and processes.

For example, a machinist may use a coordinate measuring machine to confirm the dimensions and tolerances of the machined part. These machines are more reliable than pin gauges and can measure dimensions up to five times more accurately. They can also determine how well the machined surface matches a template or another workpiece.

Speed

While the accuracy of a CNC machine shop depends on many factors, speed is one of the most important. This is because a higher rate can increase the overall output of a machine. It can also help in creating more complex designs and reducing waste.

The speed of a CNC machine shop is measured by the precision of its positioning system. This is determined by measuring the linear accuracy of a machine using a laser interferometer. Typically, this is done in an open-loop or closed-loop servo system. It is also possible to measure the squareness of an axis.

The machine shop’s ability to look ahead is another factor that determines its speed and accuracy. This is important because it allows the machine to process large blocks of data faster, allowing it to finish jobs with more accuracy. This is especially important for high-speed machining. The material’s properties also play a role in how quickly the machine can be operated.

Reliability

Whether it’s a robotic arm used in laser surgery or the landing gear elements of high-performance aircraft, precision parts are crucial to safety and efficiency. This is why it’s important to work with a machine shop that prioritizes reliability. A reliable shop will have a strong track record of meeting deadlines and providing high-quality services. In addition, they will have the necessary certifications and compliance with industry standards.

The shop’s machining experience is also an important factor to consider. The longer they’ve been in business, the more likely they are to have encountered a range of challenges and found solutions for them. They’ll be able to identify potential issues and address them quickly before they become a problem.

Another way to measure accuracy is with a coordinate measuring machine (CMM). This method measures the position of a part and compares it to a master template. This can help you avoid costly mistakes and save time in the process.

Cost

CNC machines are hefty investments, and every hour on them is critical to making a profit. That’s why accurate job-costing processes are vital to the success of your shop. These processes help you create more comprehensive quotes and make better decisions about mark-ups. They also help you identify the most cost-effective ways to use your machines.

The type of material used has a significant impact on the true cost of machining. Some materials, such as titanium matrix composites, are 10 times more expensive than aluminum alloys. And a portion of the material will become waste after cutting, which is an additional cost to account for in your calculations.

You may also need special tools for machining some types of parts, such as bespoke hole and thread diameters. These tools can be expensive, and the more complicated the part geometry is, the more time it takes to machine it. Additionally, you need to consider labor costs.