How CNC Milling Machines Save Time and Money

CNC milling machines are great for creating durable, precise parts that would be expensive, time-consuming or impossible to make by hand. But this subtractive manufacturing process can be costly if the part design is not optimized.

Adding internal corner radii, minimizing the depth of pockets, designing tapped holes, and limiting machine setups are some of the ways that you can decrease the cost of CNC milling without sacrificing the quality of the product.

Optimal Design

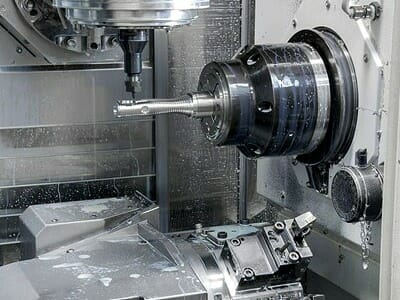

Milling machines create precise and intricate parts and designs that meet specific specifications. They do this by using a spinning tool to cut into raw material. They are ideal for custom work such as restoring old and rare cars or creating prototypes and concepts. Without a CNC, these kinds of tasks would require a shop to design the part for you, fabricate it, and ship it to you. This can eat up time and money.

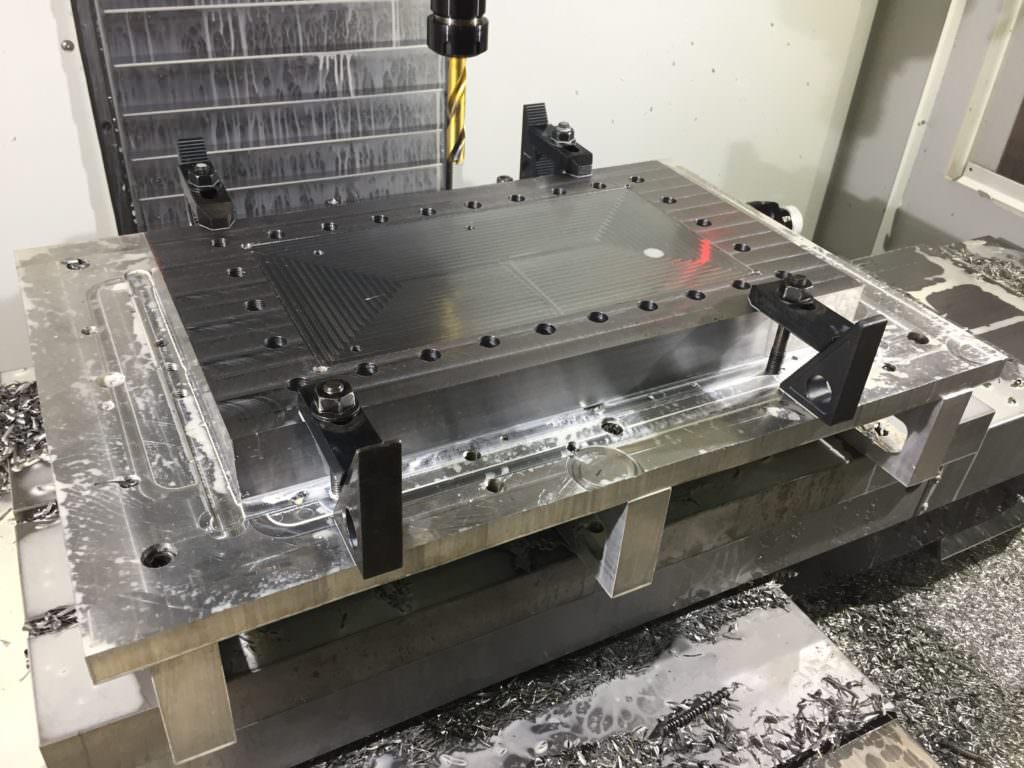

When you plan on working with a CNC machine shop like the pros at Bates Mfg & Machine in Farmersville, Texas, it is important to optimize your product design to reduce machining costs. This will help reduce startup and operating costs as well as materials costs. One example is planning on a hole size that will minimize the number of tool changes required, as each tool change will add time to the production process. Similarly, designing internal corners with a radius that is larger than the diameter of the cutting tool will reduce cost as it will be easier for the machine to cut.

Rounded Corners

Rounded corners are visually appealing because they break up sharp geometric lines and angles. In addition, they create a softer appearance that can make an object more approachable and inviting. In product design, rounded edges also promote safety. A sharp corner can easily cause a hand or head injury. In the case of a tablet or smartphone, it can be hard to use if you hit your finger against the edge.

When designing digital graphics, curved corners help us to process information faster because our brains can more easily follow the curve of the line. If the line were a straight edge, our eyes would need to stop and start every time it changed direction.

Using the Create Rounded Corner tool in the Sketch group, you can elongate a straight or angled line to create a curved arc that maintains its tangency with the adjacent line. You can use this tool on coplanar 3D lines, including those created by blending.

Deep Pockets

Deep pockets are resources or money that allow companies and individuals to take risks, invest in new technologies, hire the best talent, and weather economic storms. They can also give a company or individual a significant advantage over their competitors. Deep pockets can have positive effects on society, but they can also have negative effects like becoming too big to fail or promoting inequality.

The phrase “deep pockets” refers to financial wealth and resources, and it is usually associated with large corporations or wealthy individuals. The term has been around for centuries, and it can be traced back to the Medici family in 15th century Florence, Italy.

If you’re looking for a set of deep pocket sheets, there are plenty of options to choose from. Mellanni stocks both standard and deep pocket sheet sets in a variety of colors and fabrics, so you can find the perfect set to fit your bed. While the price of a deep pocket sheet will be slightly higher than that of a standard sheet, it will be worth it in terms of comfort.

Choosing the Right Tool

CNC milling machines are highly flexible but this also means they can come with a heftier price tag. This is especially true for larger, high-precision models that are capable of producing extremely accurate pieces but can also take longer to complete.

Fortunately, there are several ways to save on these non-recurring engineering costs (NREs) for your milling project. First, opt for a more efficient design that will reduce your overall machining time. This will help to prevent costly errors that can result from working with complex designs.

Another way to save on NREs is by choosing a machine that offers less maintenance than conventional manual machinery. Since CNC mills don’t require human operators, they can operate more quickly and efficiently while maintaining consistent precision. They also provide a safer working environment since workers are at a safe distance from the sharp implements. This also helps to save on labor costs.