How CNC Machine Manufacturing and Medical Device Manufacturing go Hand in Hand

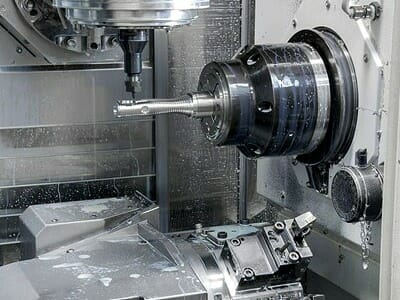

CNC machine manufacturing begins with a CAD design. This design is generated by a CAD/CAM design service company. This software lets designers create technical specifications and models of products. Using CAD software, a manufacturer can create these drawings and produce a finished product. In the early days of the industry, parsons relied on his IBM 602A multiplyer to calculate airfoil coordinates. Now, he can make the parts he wants with ease.

The medical industry is another area where CNC machining can be a big help. Because of the high-precision needed for critical medical equipment, CNC machining provides a highly accurate solution. With the latest technology and advanced software, engineers can create customized parts in a short period of time. The process can be used to ensure that the dimensions of each component are correct. Because of the high-precision, it is vital that the parts fit together correctly, as any error could result in machine malfunctions and misdiagnoses.

equipment, CNC machining provides a highly accurate solution. With the latest technology and advanced software, engineers can create customized parts in a short period of time. The process can be used to ensure that the dimensions of each component are correct. Because of the high-precision, it is vital that the parts fit together correctly, as any error could result in machine malfunctions and misdiagnoses.

Besides CNC machine manufacturing, other fields that benefit from this technology include aerospace and military products. This technology produces consistent parts that are a must for the aviation, aerospace, and medical industries. Even the slightest differences in components can cause the final product to fail. It is also used in dentistry, medicine, and the automotive industry. A CNC machine allows you to make nearly anything, including highly complex parts. In addition to precision machines, you can also buy dental scalers and fixation devices.

CNC machines are used in many industries, including the medical field. These sectors have high demands for precision and can be critical. For example, a malfunctioning piece of medical equipment can result in lives being at risk. With these high-tech systems, it is not uncommon for parts to fail without warning. The CNC machine industry makes these parts with the minimum margin of error. Because these parts are often disposable, the tolerance for error is extremely low.

CNC machines are an ideal choice for industries that need customized parts quickly and accurately. The medical industry is particularly demanding, as the FDA has strict standards for manufacturing and design. With a CNC machine, engineers can visualize the design in three dimensions and make sure that each part is the right size. A large margin of error can cause a malfunctioning machine or a medical misdiagnosis. The healthcare industry has many other benefits to CNC machine manufacturing.

The CNC machine manufacturing industry is a vital part of the medical industry. This industry needs parts to be manufactured with the highest level of precision. The CNC machine industry produces customized parts and is FDA-approved. The machining industry requires a high level of accuracy and quality. It can produce a variety of components, including electronic gears. Moreover, it can be found in the defense sector. It is essential to ensure that components are fit properly for use.

In addition to medical applications, the CNC machine industry is also important for the defense sector. The medical industry needs high-quality components for military activity. Unlike other industries, the FDA requires precision and FDA-approved environments when it comes to the CNC machine industry. It is important that a company works with a reputable supplier in this sector to guarantee that its products meet these standards. A good partner will work with an excellent CNC control system to make sure that the parts are manufactured according to the specifications of the government.

Regardless of the industry, CNC machines are highly effective in creating customized parts. The manufacturing environment should be FDA-approved, and the machine should be able to work in a clean environment. It is very important to keep the parts and machine environment clean at all times. If it’s not clean, it can lead to malfunctioning of the device. Therefore, it’s imperative to ensure that the manufacturing process is FDA-approved. If the product isn’t safe for use, it could cause complications.

Using CNC machines can create custom-made parts quickly. The medical industry requires a clean environment and high-quality parts. Because of this, the medical industry requires a certified environment. In this case, the CNC machine is the best way to produce these parts. The FDA has approved conditions for a CNC manufacturing facility. Then, the manufacturer can proceed with the manufacturing process. The finished part will be safe to use. The FDA-approved environment will ensure that it is sterile.