Choosing a Family Owned CNC Machine Shop

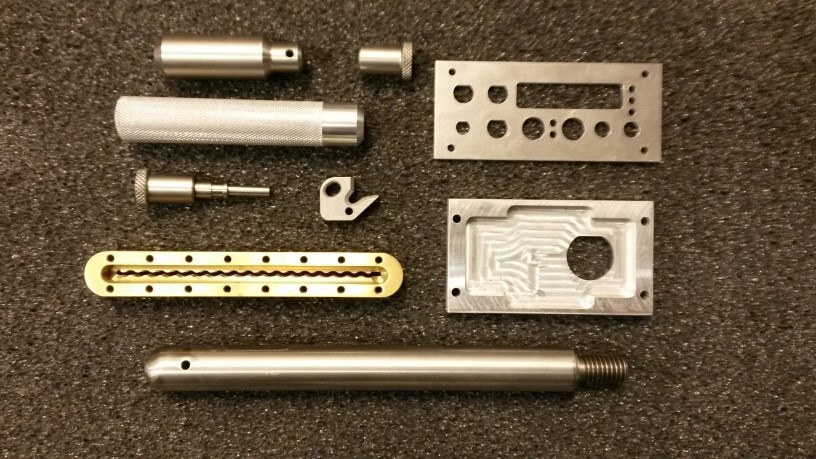

A cnc machine shop is a manufacturing shop that provides precision machining services for different industries. Bates Machine & Mfg. is able to produce products to the exact specifications of their clients, as well as meet short deadlines.

It is important for machine shops to prioritize safety in their operations. This includes training and educating employees, adhering to rules & regulations, routine inspection, and maintaining safety equipment.

Family Owned

Whether your project is small or large, it is important to find a machine shop that has experience with your particular industry. It’s also a good idea to look for shops that offer a range of services, including heat treating and anodizing, to ensure they can handle all your needs in one place.

good idea to look for shops that offer a range of services, including heat treating and anodizing, to ensure they can handle all your needs in one place.

Customer testimonials and reviews can give you insight into a company’s quality of work. In addition, checking if the shop is ISO certified shows their commitment to meeting client expectations and providing the best service.

Choosing the right CNC machine shop can be challenging. While price is a major factor in the decision-making process, the cheapest option may not be the most cost-effective in the long run. Make sure to evaluate quotes from multiple machine shops and consider factors like quality, lead time, and service. Then, you can be confident in your choice. Moreover, you should choose a shop that offers instant online quoting for a seamless procurement process.

Quality Workmanship

When choosing a machine shop, consider the quality of workmanship and how they handle their projects. Look for shops with experience working with different materials and alloys, a history of customer satisfaction, and a strong reputation in the industry. Additionally, make sure they can meet your manufacturing needs and provide you with fast turnaround times.

The first step in ensuring quality is clearly defining the project requirements and objectives. This includes identifying the desired dimensions and design requirements, as well as discussing the appropriate materials and tolerances. It is also important to communicate these requirements effectively with the machine shop, so that they can ensure the final product meets your expectations.

A reputable CNC machine shop will also use advanced technologies to ensure quality. These technologies can improve efficiency and reduce production costs by reducing the number of manual processes. They can also help to ensure accurate measurements using a coordinate measuring machine (CMM), which is used to verify the geometry of machined parts. In addition, some machine shops offer additional services like ultrasonic cleaning, which ensures compliance with sanitization regulations.

Competitive Pricing

Machine shops can be a valuable resource for companies seeking to outsource their manufacturing needs. Whether you need a single prototype or large and small-volume ongoing orders, machine shops can produce a wide range of components and deliver quality results with fast turnaround times.

Choosing the right shop for your project requires evaluating their capabilities, equipment and technology. Look for shops that offer a comprehensive range of machining services and have experience working with your desired materials. This will help ensure your products meet specifications and exceed expectations.

In addition to evaluating the shop’s equipment, you should also consider its pricing model. It’s important to find a shop that offers competitive pricing without sacrificing quality or service. A good place to start is by comparing quotes from different machine shops. Evaluate each quote against your costs and profit expectations. Be sure to include factors like turnaround time, quality assurance measures, and customer support. You should also make sure the shop offers fair terms and conditions.

Customer Service

A machine shop’s equipment can be impressive and initially attract customers, but it is the CNC precision machining team that turns vendor relationships into mutually beneficial partnerships. To accomplish this, there must be clear communication throughout the project’s production phases.

This communication must include a willingness to answer any questions or concerns, as well as proactively update customers on order status. This is a hallmark of excellent customer service, and should be exhibited during the quote process and beyond.

In addition, a good machine shop will maintain confidentiality, especially when it comes to proprietary designs. This can be accomplished by requiring all clients to sign a non-disclosure agreement prior to manufacturing. Another important consideration is a company’s turnaround time. It’s crucial that a machine shop can meet or exceed project deadlines. A flexible shop that can adapt to changing requirements is best suited for this task. This is particularly important when working with industries like military applications and shipbuilding, where quality is critical for ensuring safety and effectiveness.