Choosing a CNC Machine Shop

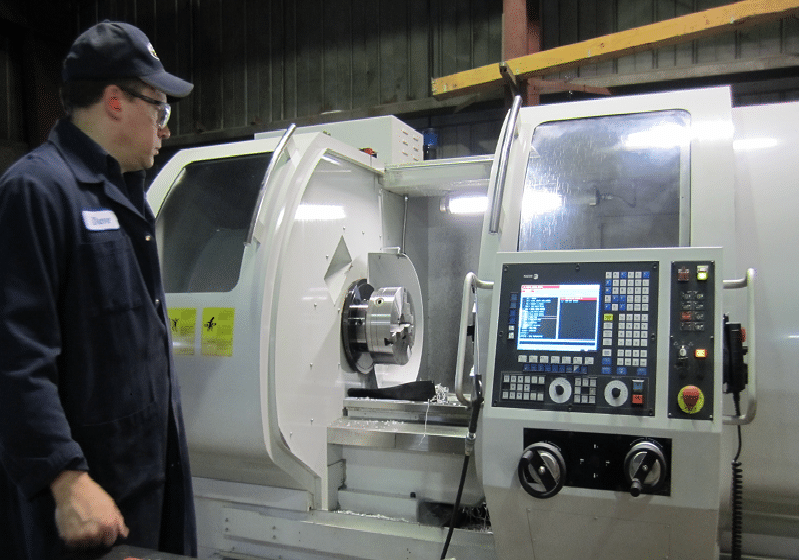

Machine shops rely on computer numerical control (CNC) to operate their machines. This technology replaced the hand-cranks and levers of old, and enables shop owners to create precise, customized parts with speed and ease.

Businesses and product developers need a machine shop with experience handling their specific machining needs. Look for a shop that can sign an NDA before working with you, as it will ensure your designs will remain confidential.

1. Experience

Working with a machine shop that has experience will ensure your product or project is completed quickly and correctly. This will save you time, money and avoid costly mistakes. Moreover, these shops can help you create prototypes for new products or test them in real-world conditions before they go into production, which will reduce your risk of failure.

time, money and avoid costly mistakes. Moreover, these shops can help you create prototypes for new products or test them in real-world conditions before they go into production, which will reduce your risk of failure.

Most machine shops work business-to-business, making custom products for other businesses to use and sell to their customers. A few are focused on specialty or niche markets and offer additional value-added services. For example, Bates Machine & Mfg. offers consulting to help streamlinethe manufacturing process.

When working with a machine shop, look for one that has an extensive range of capabilities and uses modern CNC machines and measuring equipment. Also, check that the machine shop has a good reputation and will sign a non-disclosure agreement (NDA) to protect customer designs.

2. Flexibility

Machine shops are used in the manufacturing process for a wide range of products from car parts to precision electronics. With advanced technology and automated processes, machines are able to cut metal into extremely intricate shapes that cannot be made through traditional methods. This allows for a wider range of products to be produced and makes them more accessible to consumers.

In addition, the flexibility of CNC machining can help save time when compared to manual processing. Digital models of products can be processed by the machine and converted into code that a machine then uses to cut the metal. This eliminates the need for a human operator to manually process each design, which can take up to an hour or more.

The machine shop must also have the ability to accommodate varying product requirements in terms of tolerances. For example, the shop must be able to prepare pipes that have higher wall thicknesses. They must also be able to use tools that can produce all types of bevels.

3. Customization

A machine shop must be able to work with different materials and deliver results that are perfect for their clients. They must also be flexible enough to take on different size orders. This flexibility is what enables them to provide excellent value for their customers.

It is important for a machine shop to be capable of fabricating the various products and parts that go into aerospace equipment. This is why they need to be able to handle stainless steel and aluminium at a high level of quality.

The ideal machine shop has previous samples of their work to show their experience and expertise in their industry. They should be able to explain their procedures in detail so that their clients are confident in their abilities. It is also useful for a machine shop to have an online platform through which their clients can track the progress of their order. They should also be able to communicate via phone in case of any queries.

4. Timely Delivery

Whether it’s a quick turnaround on a new project or an emergency repair, having a machine shop that is able to deliver on short notice is essential. Look for a CNC machine shop that has the equipment to produce your products quickly, without sacrificing quality.

The ability to deliver on time is a direct indicator of a CNC machine shop’s efficiency and overall capabilities. A reliable shop will have a high-quality team of expert machinists working alongside state-of-the-art machines to create parts that meet exact custom design specifications.

A reputable machine shop will also offer timely communication with its clients. Look for a company that is easily accessible to manage orders through digital mediums and utilizes feedback mechanisms to incite projects’ growth. This way, you can stay in contact with your project throughout the process and know exactly what to expect when it’s delivered. Additionally, look for shops that can offer ancillary services, such as painting or bead blasting, to shorten the lead time on your order.