Benefits of Using a CNC Milling Machine

Using a cnc milling machine allows businesses to produce bespoke parts for their products in-house, instead of paying third-party manufacturers to do it for them. This can help them save time and money.

Unlike manual milling, CNC milling machines can run on their own, producing consistent results every time. This reduces the chance of errors, resulting in a higher quality product.

Increased Productivity

A CNC milling machine is an effective way to increase productivity for your business. It allows you to produce parts at a faster rate than conventional machines and with greater accuracy, which reduces production time. Furthermore, it helps you avoid costly mistakes that can occur with manual machines.

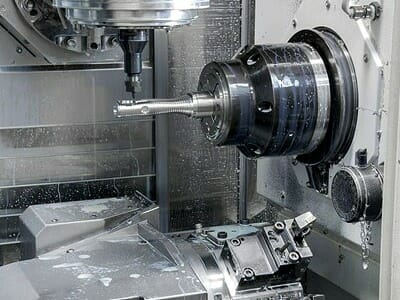

CNC mills can use multiple tools simultaneously to cut a part, eliminating the need for an operator to manually change out tools during each operation. This increases machining efficiency and improves quality. In addition, CNC mills can be integrated with robot arms to automate a wide range of tasks like loading raw material into the machine and removing or repositioning parts after machining is complete.

While a CNC milling machine is an effective tool for increasing productivity, it’s important to have a skilled team of engineers, floor technicians and a quality control team. This will help you eliminate bottlenecks and downtimes, streamline your workflow, and stay competitive.

Faster Turnaround Time

Using CNC milling machines helps to speed up the process of creating custom made parts. The design of a product only has to be programmed once and the machine will replicate it consistently and precisely, regardless of order size. This allows companies to fulfill orders more quickly and efficiently, which can save money in the long run.

These machines also require very little training and skill to operate, reducing the number of workers needed for operation and oversight. They also have many safety features that help to keep employees at a safe distance from the machines.

These machines are also energy-efficient, cutting down on energy usage. This can help reduce costs in the long run, as well as helping to improve overall sustainability. This can be especially important for businesses that produce large amounts of products on a regular basis. This can allow them to cut down on production time and still maintain high quality standards.

Increased Precision

Precision is key in some applications, and a cnc milling machine can help ensure the product meets standards. This means fewer rework cycles and better customer satisfaction.

Since CNC machines rely on coded software to fabricate parts, they bypass the possibility of human error. This allows for tighter tolerances that are typically not possible with conventional manual machines.

The precision of a CNC milling machine can be enhanced through automation strategies, quality control protocols, and regular maintenance checks. It is also important to understand how factors like machine design, chatter, and coolant influence accuracy.

A chip conveyor keeps the machine clean and efficient, reducing downtime from cleaning up chips. It also helps maintain the stability of the cutting tool, which improves efficiency and reduces tool wear. It can also reduce the number of parts that need to be inspected. This can save time and money for the manufacturer, resulting in higher productivity. Moreover, it helps to improve safety by keeping workers at a distance from the machine’s sharp tools.

Increased Flexibility

Unlike a manual lathe, drill or punch where the operator comes into direct contact with the implement, CNC machines operate remotely. This allows the operators to remain at a safe distance and eliminates any physical fatigue or injury.

For complex geometries, a five-axis machine can remove more material in a single pass and reduces tool wear, making it an efficient solution for demanding jobs. These machines also offer a more precise finish and premium tolerances.

Adding a gantry or robot can enable the machining center to lift and move parts between work cells, eliminating the need for manual intervention and increasing production flexibility. This is particularly useful for jobs where the same part is repeated frequently – such as oil and gas fabrication. A cnc milling machine can also be used in conjunction with a programmable turret to perform simultaneous cutting and drilling operations on the same piece, significantly speeding up production times. This helps to improve uptime and reduces overall operating costs.