Advantages of Working With a CNC Machine Shop

A cnc machine shop needs to offer a variety of services. These include machining, painting, and impregnating. They also need to provide a high level of quality assurance.

A good cnc shop will have an independent quality assurance team. This will help to reduce production time and ensure that the final product meets quality standards.

Cost-Effectiveness

Compared to manual machines, CNC machine shops offer several advantages. These include lower production costs, better accuracy, and a higher level of customization. Moreover, they are capable of producing complex parts that are not feasible with other techniques.

The cost of a CNC job depends on its complexity and the type of materials used. The more intricate the design, the more time and effort it will require to manufacture. The use of custom tools and tight tolerances also increases the cost. Similarly, materials like titanium and stainless steel are more expensive than aluminum and plastics.

It’s important to select a shop that offers efficiency and reliability. You should also choose a shop that is honest about its capabilities. This will help you avoid the costly mistakes that many people make when deciding on a machining company.

Accuracy

One of the most important aspects of a machine shop is its accuracy. This is defined as how well a machine performs an operation to the specified parameter. For instance, if a programmer inputs instructions to drill a hole 5 inches from the edge of a rod, an accurate CNC machine will do this without fail.

This level of precision is critical for businesses that produce products that consumers rely on, like airplanes and automobiles. Even the smallest deviation in part dimensions could result in failure and endanger the lives of drivers and passengers.

It’s best to choose a shop that is experienced and understands the importance of precision. A reputable shop will also be willing to sign a Non-Disclosure Agreement (NDA) before starting work.

Time-Saving

Using CNC machining cuts down on development, setup and production times, which means raw materials become finished products more quickly. This leads to a quicker turnaround on delivery orders.

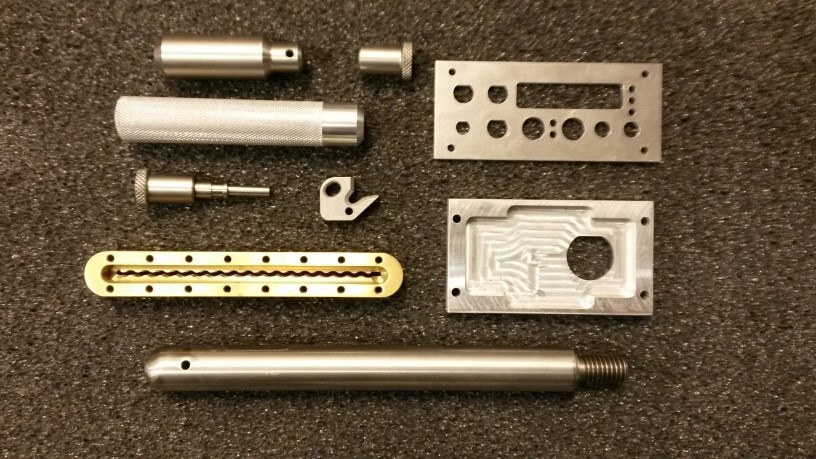

A reputable machine shop offers a variety of equipment including milling machines, machining centers and lathes. Some also have electrical discharge machining equipment. They also have surface finishing tools that help produce items with a gloss look, polished finish or whatever the client requests.

A good company should monitor its workers when they are operating machinery. They should not be ill, inebriated or taking any performance-affecting medication. They should also keep their machines clean to prevent slippage and prevent a potential fire hazard. They should also be willing to learn from their mistakes and change procedures accordingly.

Flexibility

Machines require fewer employees to operate, freeing up space and increasing production scalability. This makes CNC machines a good choice for businesses that need to produce large quantities of parts or meet tight turnaround times.

This technology offers high accuracy, reduced development, setup and production times, and improved planning capabilities. It can also reduce the need for costly tooling.

It is important to choose a shop that is efficient and reliable. They should be able to complete the job within your deadline and provide quality products. They should also sign a non-disclosure agreement to ensure that your design stays private. It will protect your business from competitors and prevent leaks of confidential information. Additionally, the shop should have a QA team that can perform in-process and final inspections to ensure consistency.

Reliability

Reliability refers to the ability of a shop to deliver products according to agreed upon specifications. A reliable CNC machine shop follows strict quality control procedures and uses equipment such as pin gauges to ensure that the finished product complies with the original dimensional requirements.

In addition, a trusted CNC machine shop will respect the confidentiality of your business and product designs. They should be willing to sign a Non-Disclosure Agreement (NDA) and be honest about what they can and cannot do.

Additionally, a trusted CNC machine shop will have experienced machinists, modern CNC machines, and standard measuring equipment. They should also keep their machines clean to prevent slippage and the buildup of dust or scrap metals, which may be a fire hazard. Workers should also be healthy and not attend work if they’re sick or taking performance-affecting medication.