Is CNC Outsourcing Right For You?

CNC outsourcing has become a game-changer for businesses operating in competitive markets. Whether you’re a small business owner, a manufacturing company, or a product designer, outsourcing CNC (computer numerical control) machining can provide you with access to top-tier equipment, expertise, and cost-saving solutions. However, like any business decision, it also has its challenges.

Understanding CNC Outsourcing

What is CNC Machining?

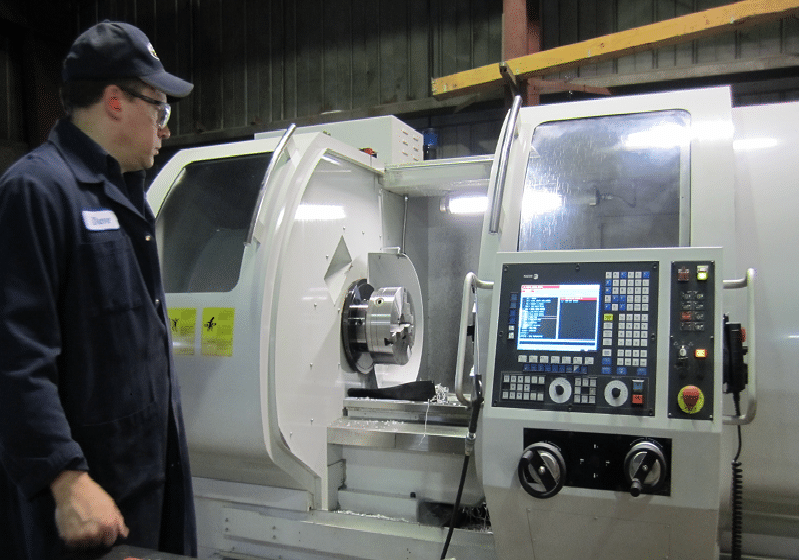

CNC machining is a manufacturing process in which pre-programmed computer software controls the movement of tools and machinery to create precise parts and products. From milling to cutting and drilling, CNC machines can handle various complex tasks with exceptional accuracy.

What Does CNC Outsourcing Mean?

CNC outsourcing refers to partnering with a third-party CNC service provider to handle the manufacturing processes of your product components. These providers use specialized equipment and skilled technicians to produce custom parts for their clients.

components. These providers use specialized equipment and skilled technicians to produce custom parts for their clients.

Types of CNC Outsourcing Services

CNC outsourcing encompasses a wide array of services, depending on your production needs:

- Parts Manufacturing: Third-party providers handle the creation of custom components for specific products.

- Laser Engraving: Precision engraving for branding or customizing products.

- Welding/Fabrication: Services that involve combining and shaping materials into finished parts or structures.

By understanding the different services available, you can identify which options align best with your production requirements.

The Advantages of CNC Outsourcing

CNC outsourcing offers several significant benefits that can enhance your business operations:

1. Cost Savings

Investing in CNC machinery and training employees can be prohibitively expensive, particularly for small businesses. Outsourcing eliminates the need for these upfront costs and reduces ongoing expenses, including maintenance, depreciation, and facility overheads.

2. Access to Expertise and Advanced Technology

Outsourcing gives you access to skilled technicians and cutting-edge equipment like the Haas VF2SSYT Mill or Leadwell T-7 Lathe. These technologies, paired with experienced professionals, ensure high-quality results that may be difficult to achieve in-house.

3. Scalability and Flexibility

Markets often experience fluctuating demand. With outsourcing, your production volume can be easily scaled up or down without additional investments in equipment or staffing. This flexibility is ideal for responding to seasonal changes or sudden spikes in customer demand.

4. Faster Turnaround Times

Professional CNC providers are equipped to deliver faster results. Their advanced machinery and dedicated teams ensure that products are manufactured and delivered more quickly compared to in-house production.

5. Focus on Core Competencies

Outsourcing manufacturing tasks frees up resources and time, allowing your business to focus on its core strengths, such as design, marketing, or customer relations.

The Disadvantages of CNC Outsourcing

While CNC outsourcing has clear benefits, it’s essential to consider its potential drawbacks:

1. Communication Challenges

Working with an external supplier may present language barriers, time zone differences, or miscommunications regarding project specifications, which could affect timelines or product quality.

2. Quality Control Concerns

Ensuring that outsourced components meet stringent quality standards can be challenging. Partnering with a reliable CNC provider with robust quality assurance processes is crucial.

3. Intellectual Property Risks

Sharing sensitive designs or proprietary information with a third-party provider may pose risks to intellectual property. Non-disclosure agreements and data security measures are key to mitigating this concern.

4. Shipping Costs and Logistics

Outsourcing can incur additional shipping and logistics costs, especially when working with distant suppliers. Delays in transportation could impact production schedules.

5. Dependency on External Suppliers

Relying on an external partner for critical components introduces a dependency. Any disruption in your supplier’s operations could directly affect your production.

Key Considerations Before Outsourcing

Before deciding on CNC outsourcing, consider the following points:

1. Define Project Requirements

Clearly outline your project specifications, including material types, part dimensions, production quantity, and deadlines. Providing detailed requirements minimizes confusion and errors.

2. Research Potential Partners

Vet CNC providers thoroughly. Look into their reputation, reviews, previous projects, and range of services offered. For instance, companies like Bates Machine & Mfg. in Texas are known for their expertise and reliability.

3. Assess Quality Control Processes

Ensure the provider has a strong quality assurance system in place to maintain high standards for their output.

4. Data Security Measures

Verify that the provider implements stringent data security policies to protect your intellectual property and sensitive information.

5. Communication Protocols

Establish clear and regular communication channels to address questions, monitor progress, and ensure alignment throughout the project.

Real-World Examples and Case Studies

Successful CNC outsourcing stories showcase how businesses have improved efficiency and reduced costs. For example, Bates Machine & Mfg. helped companies optimize production by utilizing state-of-the-art CNC machines like the Hurco KMB-1 or the Epilog Helix 50w Laser Engraver.

Not only did these businesses save on the cost of equipment and labor, but they also achieved faster project completion, allowing them to bring products to market more quickly.

Common CNC Materials

Understanding material options is essential for CNC outsourcing projects. Common CNC materials include:

- Metals: Aluminum (6061-T6, 7075), Brass, Copper, Steel (C1018, 4140), Stainless Steel (303, 316, 17-4 PH).

- Plastics: ABS, Acrylic, Delrin, HDPE, Nylon, Polycarbonate, Teflon.

These materials offer different benefits in terms of durability, weight, and resistance, so choosing the right one is critical to the success of your project.

Make the Right Choice for Your Business

CNC outsourcing is a powerful tool that offers cost savings, improved efficiency, and access to expertise and technology. However, it also comes with challenges like quality control concerns and dependency on external suppliers. Whether outsourcing is the right strategy for your business depends on your unique needs, resources, and goals.

By carefully evaluating the benefits, risks, and key considerations, you can make an informed decision that positions your business for success in a highly competitive market.

Thinking about CNC outsourcing for your next project? Start exploring reputable providers like Bates Machine & Mfg. and see how outsourcing can take your business to the next level.