CNC Production Outsourcing: A Path to Efficiency and Growth

Manufacturers, small businesses, and entrepreneurs are always exploring new strategies to stay competitive and streamline operations. One increasingly popular solution is CNC production outsourcing. By leveraging specialized capabilities and external expertise, companies can not only reduce production costs but also enhance product quality and focus on innovation.

If you’ve wondered whether outsourcing CNC production is the right approach for your business, you’re in the right place. This guide will explore the benefits, considerations, and steps for successful CNC outsourcing, ensuring you can maximize efficiency and profitability.

What is CNC Production Outsourcing?

Understanding CNC and Its Role in Manufacturing

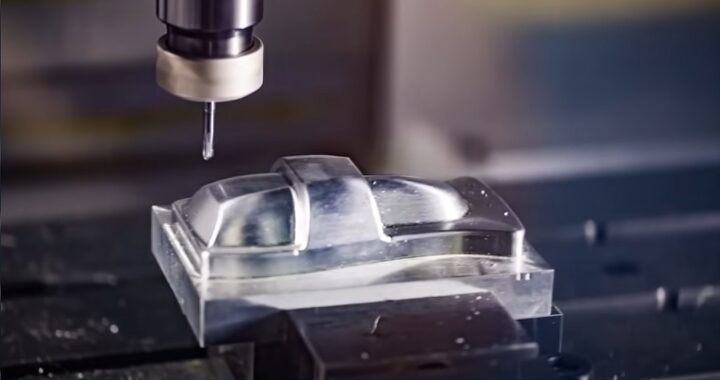

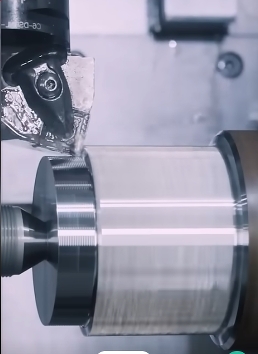

CNC, or computer numerical control, refers to an advanced manufacturing process where pre-programmed software controls tools and  machinery to create precision parts and components. CNC is widely used across industries, from aerospace and automotive to medical devices and consumer electronics, due to its ability to produce intricate, high-quality items with consistency.

machinery to create precision parts and components. CNC is widely used across industries, from aerospace and automotive to medical devices and consumer electronics, due to its ability to produce intricate, high-quality items with consistency.

However, acquiring and maintaining CNC machines and the expertise needed to operate them can be costly and time-consuming. This is where CNC production outsourcing comes in. Outsourcing allows businesses to delegate CNC machining tasks to third-party providers who specialize in advanced manufacturing capabilities.

Why Do Companies Outsource CNC Production?

The decision to outsource CNC machining often stems from challenges related to cost, lack of specialized equipment, or bandwidth limitations. Outsourcing offers an opportunity to overcome these challenges by leveraging external expertise and resources.

The Benefits of CNC Production Outsourcing

1. Cost Savings

Setting up and maintaining an in-house CNC facility can be a significant investment. Costs include purchasing expensive CNC machines, hiring skilled operators, and covering regular upkeep. By outsourcing, businesses avoid these upfront expenditures and instead pay for production based on specific projects or outputs.

This is particularly beneficial for small businesses and startups that may lack the capital to invest in full-scale CNC facilities.

2. Access to Specialized Equipment and Expertise

CNC outsourcing partners, like Bates Machine & Mfg. based in Farmersville, Texas, often have state-of-the-art machinery and highly experienced professionals. This allows businesses to access capabilities they may not have in-house, such as 5-axis machining or precision grinding.

Collaborating with specialized partners ensures that production quality is maintained and often elevated, giving companies a competitive edge in their markets.

3. Focus on Core Business Functions

By offloading time-intensive CNC machining tasks, teams can focus on innovation, product development, and other core business functions. Outsourcing removes the burden of managing complex manufacturing operations, allowing businesses to dedicate resources to their primary goals.

Key Considerations for Choosing an Outsourcing Partner

Making the right choice of outsourcing partner is critical to the success of your projects. Here’s what to look for in a CNC production outsourcing provider:

1. Quality Standards and Certifications

Your partner should adhere to rigorous quality standards, such as ISO certifications, to ensure that the parts produced meet your specifications.

2. Clear Communication Practices

Effective communication is essential for a smooth collaboration. Look for a provider that offers consistent updates, clarifies technical details, and listens to your concerns.

3. Production Capacity

Does the outsourcing partner have the capacity to scale up or down based on your needs? Assess their workload capabilities to ensure timely project delivery.

4. Geographic Location

While global outsourcing can provide cost savings, local providers like Bates Machine & Mfg. may offer advantages such as faster lead times and easier communication.

Overcoming Common Challenges in CNC Production Outsourcing

1. Time Zone Differences and Language Barriers

Working with overseas CNC providers can present challenges related to time zones and communication. Establishing clear expectations for response times and using project management tools can help mitigate these issues.

2. Intellectual Property Protection

When working with third-party manufacturers, ensuring the security of your designs and intellectual property is crucial. Implement confidentiality agreements or NDAs to protect your business.

3. Quality Control

Maintain oversight by establishing quality benchmarks and conducting regular inspections of the output. Partnering with providers like Bates Machine & Mfg., known for their commitment to precision, can alleviate concerns about quality.

How to Manage an Outsourced CNC Project

Outsourcing does not mean relinquishing control of the project. Here’s how to ensure smooth operations when working with an external CNC provider.

Set Clear Expectations

Define project requirements, deadlines, and expected outcomes from the start. Ensure both parties are aligned about goals and deliverables.

Use Collaboration Tools

Leverage project management tools, such as Trello, Slack, or Monday.com, to share updates, track progress, and maintain transparent communication throughout the project lifecycle.

Build a Strong Relationship

Treat your outsourcing partner as an extension of your team. Regular check-ins, honest feedback, and collaboration on problem-solving will lead to better results over time.

Real-World Success Stories in CNC Production Outsourcing

Example 1: Optimizing Supply Chain for a Growing Manufacturer

A small automotive parts business lacked the capacity to meet increasing demand. By outsourcing CNC production to an expert provider, they reduced lead times by 25% and improved product quality.

Example 2: Startups Leveraging Expertise

A medical device startup partnered with Bates Machine & Mfg. for highly specialized machining needs. Instead of investing heavily in equipment, they accessed top-notch capabilities at a fraction of the cost, enabling faster time-to-market.

These real-world results showcase how thoughtful CNC outsourcing can lead to growth and competitiveness.

Unlock Efficiency and Growth with CNC Production Outsourcing

CNC production outsourcing offers a cost-effective, efficient, and scalable solution for businesses aiming to optimize their operations. From cost savings and access to expertise to focusing on core functions, outsourcing can transform your business processes.

By choosing a reliable partner like Bates Machine & Mfg., you can ensure precision, quality, and a collaborative approach to meet your unique needs.

Take the first step toward transforming your manufacturing operation—contact us today to explore CNC production outsourcing!