Benefits of CNC Production Outsourcing

Whether it’s prototyping or production, CNC machining services at Bates Machine & Mfg. provide significant benefits to businesses. A professional machining shop will have the expertise, equipment, and track record necessary to deliver a high-quality product in a timely manner.

Outsourcing also saves space and money by eliminating the need for expensive CNC machinery. This allows companies to invest their capital in other important aspects of the business.

Cost-effectiveness

Producing CNC precision machined parts requires significant upfront investment in equipment and skilled labor. It can also be expensive to  maintain and upgrade equipment over time. Outsourcing to a contract manufacturer can reduce these costs and free up valuable resources for other critical business functions.

maintain and upgrade equipment over time. Outsourcing to a contract manufacturer can reduce these costs and free up valuable resources for other critical business functions.

In addition to the initial cost of the machinery, it’s important to consider additional expenses, such as material waste and machinist labour rates. A specialized manufacturing partner can help you achieve cost savings through a number of techniques, including efficient machining processes and inventory management strategies that minimize costly downtime.

Another advantage of outsourcing is that it allows you to scale up or down production to meet demand. This can be particularly beneficial for a small or new company that may not have the resources to purchase and operate a CNC machine. Additionally, a reputable contract manufacturer will have the equipment and experienced personnel to quickly respond to shifts in demand.

Quicker completion times

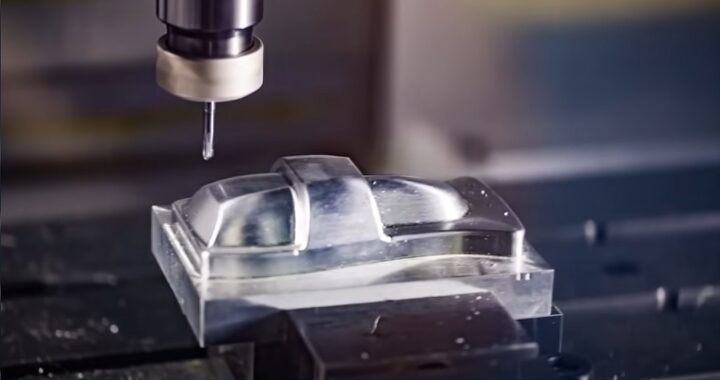

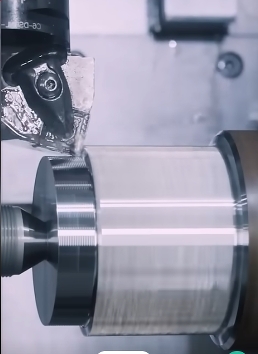

CNC machining uses computer programming to dictate the movement of factory tools, resulting in superior quality and faster completion times. By outsourcing this work to a trusted supplier, companies can minimize their upfront investment and maintenance costs.

By working with a reputable sourcing partner like SyncFab, aerospace parts procurement supply chain executives can access the expertise and technology they need for precision machining without incurring the associated labor costs and overhead expenses. This enables them to scale up or down production capacity based on demand, thereby saving money and maintaining a competitive advantage.

Additionally, outsourcing CNC machining services can improve the customer service experience. By providing clear communication, a reliable sourcing partner can address any concerns or issues quickly and efficiently. This can help ensure that customers are satisfied with the final product and lead to repeat business. Moreover, a reliable sourcing partner can also provide access to cutting-edge technologies that may not be available in-house.

Flexibility

Producing CNC precision machined parts in-house requires a significant upfront investment and skilled labor. Outsourcing these tasks to a contract manufacturer allows companies to save money and focus their internal resources on other business operations.

A professional machining shop has specialized expertise and equipment that can produce high-quality products faster and more efficiently than an in-house team. This reduces overall operational costs and enables businesses to respond quickly to changing market conditions.

When selecting a partner, consider their industry expertise, equipment, track record, accessibility, and customer focus. Additionally, ensure that the manufacturing company is ISO 13485, AS 9100, or IATF 16949 certified. It’s also important to establish effective communication and monitoring mechanisms to prevent any quality problems from occurring. This is an area where a trusted third-party supplier manager can help. SyncFab is one example of a vendor manager that can streamline the process of finding US manufacturers for precise CNC machining. Using the SyncFab platform, supply chain executives can easily find a CNC machining expert that meets their specific requirements.

Quality

CNC machining is a high-tech process that can enhance quality while reducing production time. The machines provide more precise results and reduce waste, resulting in lower overall costs. However, it is important to select a reputable, qualified service provider that understands your industry and product requirements. This will ensure that the machined components and parts meet your quality specifications.

It is also important to choose a service provider that is flexible enough to handle change orders. This will allow you to quickly scale up or down your production capacity based on market demand.

CNC machining is a high-tech service that was once only available to large corporations and businesses, but it is now accessible to small businesses through machine as a service (MaaS). It offers numerous benefits, including cost savings, improved productivity, and skilled technicians. These benefits can be leveraged to drive revenue growth for your business. In addition, it reduces inventory levels and overhead liabilities, which can improve cash flow.