Why Small Businesses Should Use Bates CNC Outsource Production

CNC Outsourced Services

Running a business of any size requires keeping operating costs low and profit return high. Adding additional equipment or hiring new employees can be costly for small and large companies.

Outsourcing CNC machining services allows companies to avoid high upfront expenses and focus on other important aspects of their business operations. However, it’s important to choose a provider that focuses on customer service and is flexible in accommodating changes.

Cost-Effectiveness

Production of CNC precision machined parts requires significant investment in equipment, software and skilled labor. Especially for small  businesses and startups, this can be an expensive proposition. By outsourcing their product manufacturing to a contract manufacturer, companies can save on these upfront costs and focus on other critical aspects of business operations.

businesses and startups, this can be an expensive proposition. By outsourcing their product manufacturing to a contract manufacturer, companies can save on these upfront costs and focus on other critical aspects of business operations.

Contract manufacturers have the necessary equipment and skill sets to produce high-quality components. They also use the latest CAD/CAM software to convert designer 3D models into machining commands. This ensures that the final product meets strict specifications and quality standards. This will help companies to maintain high customer satisfaction levels and reduce costly human error during production.

Outsourcing services can also help companies with their inventory management. They can optimize the inventory of raw materials and avoid costly shortages. This will help them to meet unforeseen demand fluctuations without having to invest in new machinery or hiring additional staff. This will give them a competitive edge over their competitors, who may not have the flexibility to scale up or down their production capabilities.

Time-Saving

A small shop will save on initial costs by outsourcing its machining services to a contract manufacturer. This will avoid the need to purchase specialized equipment, hire employees, and pay for costly maintenance overheads. It also saves time, as the manufacturer can provide precision parts in the quantities and at the times required by the company.

A reputable contract manufacturer will have the technology, skills, and equipment necessary to produce CNC machined parts efficiently. This will reduce production costs and improve the company’s competitive edge. In addition, outsourced production will allow the company to focus on its core business activities and enhance its growth potential.

The decision to outsource cnc machining is a strategic one that balances cost, technology, and flexibility. Companies need to carefully consider their needs, establish an effective cooperation mechanism, and stipulate clear responsibilities and rights in the contract. This will prevent intellectual property risks and ensure the quality of the final product.

Expertise

When it comes to CNC machining, experts can help businesses achieve high precision and accuracy. They can also provide prototype design services, which eliminates upfront costs and helps companies avoid costly mistakes. In addition, outsourcing allows companies to focus their resources on other critical business operations.

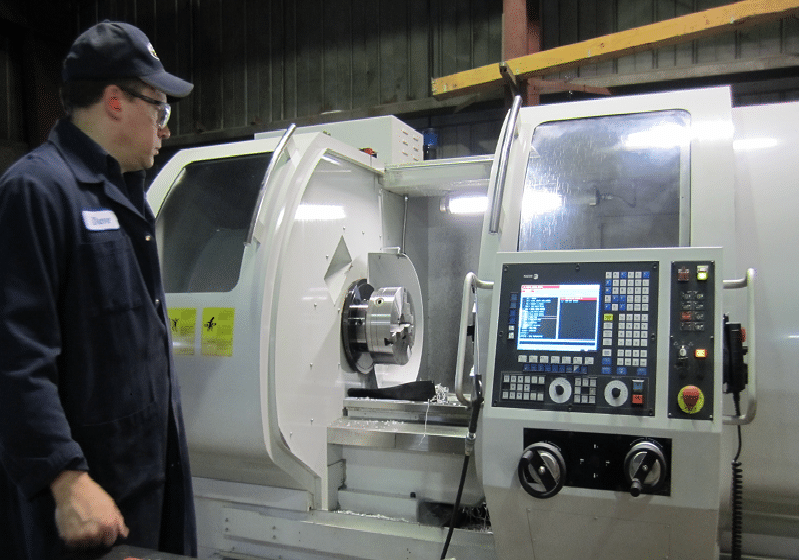

CNC machines require specialized tools and training to operate properly. This equipment is expensive, and small companies may not have the funds to afford it. Outsourcing can reduce the cost of operating these machines and save on maintenance and labor costs.

Bates Machine & Mfg. is a reliable CNC machine shop in Dallas, TX, that offers quality work and excellent customer service. Their team is well-trained and experienced, ensuring they deliver accurate results. Their focus on quality and customer satisfaction makes them a valuable partner for any company. They have a wide range of experience working with a variety of industries, including aerospace and automotive. Their expertise and experience make them a great choice for your next project.

Flexibility

CNC machining is a crucial process for manufacturing parts and products, including hydraulic cylinders, automotive components, instruments used in optoelectronics and many other types of equipment. While purchasing and operating this machinery can be a significant upfront investment, outsourcing to a contract manufacturer provides several benefits for small shops.

These services reduce the costs of equipment and employee wages, providing a more cost-effective alternative to in-house production. They also eliminate the need for training and maintenance, allowing companies to allocate these resources to other critical areas of the business.

Finding a reliable contract manufacturing company is essential. Look for one that offers a range of services, a customer-focused approach to collaboration and a strong commitment to innovation. Also, ensure that your contractor understands the importance of preserving intellectual property rights. This will help prevent infringement issues and protect your business from potential liabilities. Lastly, consider whether the service provider can provide rapid increases or decreases in production capacity as needed.