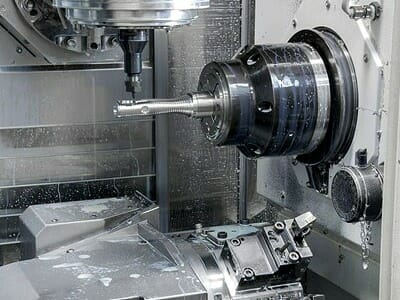

CNC Milling Production Outsourcing

In a competitive manufacturing market, companies and even small inventors and hobbyists need to be able to provide their customers with high-quality products in a timely manner. Outsourcing CNC milling work to Bates Machine & Mfg. in Farmersville, Texas is a great way to improve your company’s efficiency and competitiveness by reducing production costs and improving the quality of your final products.

In-house machining can be costly, especially for smaller businesses that may not have the financial resources to invest in CNC equipment and train new employees. Outsourcing to a professional machining shop can save you money and time, as well as provide your business with access to state-of-the-art technology.

Another benefit of outsourcing your cnc machining is faster completion times. Outsourcing companies typically have better machinery and a team of technicians who can help you get your products to the market quicker. This is especially important in a competitive manufacturing environment, where quick product launches can give you an edge over the competition.

Outsourcing also gives you the flexibility to scale your production to match your current demand. This is a great option for companies and small businesses who experience a spike in industry or marketplace demand, as it allows them to quickly adapt their production capacity without the need to invest in new equipment or hire additional staff. This can significantly reduce your overall project costs and boost your bottom line.

Common Production Outsourcing CNC Materials

• Aluminum – 2024-T351 , 6061-T6 , 6063-T3 , 7075 ,Plate , Cast

• Brass – Naval 464, Alloy 360 , Alloy 260 Yellow , Bronze

• Copper – ETP, Oxygen Free 102, Alloy 110

• Steel – C1018 , 1045 , 1144 Hi Stress ,12l14 , 1215 , 4140 , 8620

• Stainless Steel – 303 , 304 , 316 , 420 , 17-4 PH , Tool

• Plastics – ABS, Acrylic, Delrin, HDPE, Nylon , Polycarbonate (Lexan), Teflon

CNC Machines

Haas VF2SSYT Mill 30" x 20" x 20"

Leadwell V30i Mill 30" x 20" x 26"

Leadwell T-7 Lathe

Hurco KMB-1

Manual Machines

Mazak Lathe 20" x 120"

Okuma Lathe 20" x 60"

2x Nardini MS-1440 Lathes

4x Bridgeport Mills

Alliant Mill

DoAll Surface Grinder

Other Equipment

Kalamazoo H 310A Automatic Bandsaw

Ramco Horizontal Bandsaw

Hobart Vertical Bandsaw

Epilog Helix 50w Laser Engraver

Lincoln Arc Welder

Miller Mig Welder

5000 lb. Forklift

Various deburring and polishing equipment

Production Machining Outsourcing

Production outsourcing is the practice of contracting someone outside of your company to do part or all of a product's production. This can save companies money on production costs, especially when labor and equipment are concerned. It can also reduce the need for expensive facilities that require significant maintenance overheads. This can also help companies avoid high startup costs associated with new machinery, technology upgrades, depreciation, and recurring expenses like rent, insurance, utilities, and real estate taxes.

Additional Production Outsoursing Services Offered

Parts Manufacturing

Laser Engraving

Welding/Fabrication