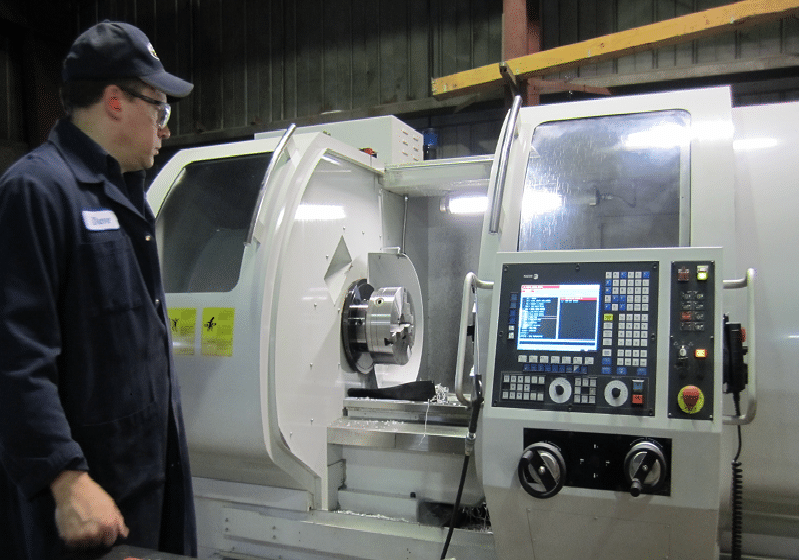

Accurate CNC Machine Tools Get The Job Done Right

It is very important to have accurate CNC machine tools in order to get the job done right. When your CNC machine is offline, you can not complete the project and complete all of your jobs. You may even end up having to re-do some materials. Accurate CNC machine tools help to make sure that every job is accurate and therefore is worth the money you pay for the machine. Therefore, it is a great idea to find a CNC machine shop in Dallas that has a high quality CNC machine.

Positional accuracy is extremely important with CNC machine tools. The better the CNC machine tools, the better your work will be with the materials you choose to work with. The higher the accuracy desired, the more costly the equipment you’ll need to purchase. In addition, you’ll want the best material to work with. To ensure the highest level of CNC machine accuracy, it is vital to choose modern CNC machine tools that have excellent Positional Accuracy Solutions.

There are different types of CNC machine tools for each purpose and job. Some CNC machines can program or reprogram on the fly based on what you see in the file. Others still allow the user to program and set parameters in the future, but those parameters will take effect today when the job is done. Positional accuracy is achieved by using two separate axes for the machine. The two axes move together, but they can also vary separately.

The two main axes used with CNC machines are the x and y coordinates. In order to have good CNC machine accuracy, it is necessary to be using the correct coordinates on both of these axes. These are referred to as “linear” and “radial”. When CNC lathes start operating with linear parameters, they can often produce a smoother result, but the accuracy level is less than ideal. This is because CNC lathes can only deal with radial parameters.

CNC machines using linear levels provide the smoothest result. Because CNC lathes can operate with higher levels of precision than traditional CNC machines, using the right CNC machine tool with the appropriate software can increase the precision of your CNC machined products. CNC lathes can use different software programs to adjust their level of precision. Some of these software programs can even allow you to reset your machine back to higher levels if your original CNC lathe has been reset.

As your CNC machine gets closer to its accuracy goal, there are several things you can do to not only save time but also help improve your CNC machine accuracy. You should always make sure to use the appropriate tools for the job you are performing. If you are using a CNC machine to manufacture brass, you should avoid using steel or carbon as the blank material. Using any material other than brass in this case will almost always cause a decrease in the quality of the end product. You should also use the appropriate clamps on the spindle as well.

The last tip to use for increasing machine accuracy is to keep your CNC machine in good working order. This means that you should lubricate your machine tool with proper grease before each use. This is particularly important to do when your CNC machine is being used to manufacture brass components. Improper lubrication can result in your CNC machine working incorrectly, which can affect the quality of the end product you are producing or the number of parts you need to finish a certain project. Keeping your CNC machine tooled and maintained properly can help it run more accurately and smoothly, which can help you save time as well as money on rework as your CNC machine is produced more efficiently.

These are just a few simple tips to use to increase the accuracy of your CNC machines. These tips will help increase the tight tolerances as well, but the ultimate way to improve machine performance is to take your machine tooling and machine building experience to the next level. By adding higher-end CNC machine tools such as CNC router bits and CNC drill bits you can increase the accuracy of your CNC machinery considerably. These tools can be expensive, but they will pay off in the long run when you can produce precision components in high volume