Choosing a CNC Machine Shop in Dallas

If you’re looking for a machine shop to produce precision machined parts, you want great service, top-notch quality and on-time delivery. Choosing the right one can be difficult.

Some machine shops specialize in aerospace machining work, medical device machining or oil and gas machinery. Others offer a wider range of services and can handle short- or long-run production machining like Bates Machine & Mfg.in Farmersville,Texas.

Cost-effectiveness

When it comes to paying a cnc machine shop in dallas for parts manufacturing, you want to make sure that you are getting the most cost-effective service possible. A reputable machine shop will have the latest technology and equipment to reduce costs, and will have quality control measures to ensure that your parts are produced accurately.

control measures to ensure that your parts are produced accurately.

If a part requires a large amount of work to create, the cost per unit will increase. This is because the machinists will be required to spend more time on the project, and this may lead to mistakes. Ultimately, this can result in a loss of revenue.

To minimize these expenses, it is best to order multiple similar parts at once. This can reduce the setup and programming times, as well as improve accuracy and efficiency. Additionally, it is a good idea to look for shops that offer online ordering and payment. This will enable you to track and monitor your orders in real-time.

Accuracy

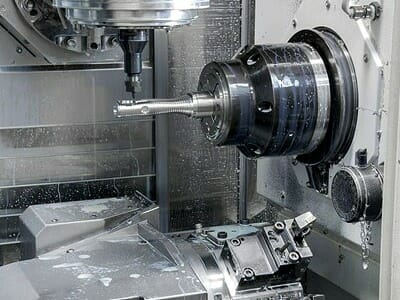

A CNC machine shop is a place where skilled machinists use machines to create precision metal parts. It can be a standalone business or part of a larger manufacturing facility. In addition to producing components, these shops also repair and maintain their machines.

A good machine shop will have an experienced staff and the right tools for the job at hand. It’s a good idea to find out how long they have been in the business, as well as what kind of work they specialize in. For instance, if you need machining done for the oil field, it’s important to know whether they have experience with that particular industry.

You should also consider whether the machine shop has any other services available, such as finishing, powder coating, anodizing, and sandblasting. This can save you time, money, and hassle in the long run. Also, a quality machine shop will follow strict quality control inspections during every phase of production.

Efficiency

Machine shops are a vital part of the manufacturing process. They produce metal parts that are used in various products, from oil field equipment to medical devices. They employ a variety of tools, including lathes, mills, and grinders to create precision-machined components. They also work on prototypes and short-run production to meet customer specifications. They are committed to achieving sustainability and eco-friendliness by reducing their carbon footprint and using recycled materials.

In addition, the machine shop can save you money by allowing you to outsource your machining needs. This allows you to focus on other important aspects of your business, and will help to increase profitability. Moreover, CNC machinery requires less manpower to operate, compared to traditional machines that require many people to handle.

When selecting a machine shop, look for one that has extensive experience in the field and uses cutting-edge technology. You should also check its technical capabilities, quality control measures, customization options, and turnaround time.

Customization

Many reputable CNC machine shops provide a one-stop-shop for their customers’ machining needs. They offer everything from a quick turnaround to post-production services like painting, powder coating, anodizing, and sandblasting. They also use advanced technologies such as waterjet, plasma, and laser cutting to accurately cut metal parts and components. This allows them to meet the exact specifications and requirements of their clients.

Precision machined parts take meticulousness machining to the next level, and only the best CNC shop can deliver results that can withstand the demands of different environments. This is especially true for medical precision parts, which must be accurate to tolerances that the human eye cannot discern.

The University of Texas at Dallas has a dedicated machine shop that provides support for both teaching and research activities. The shop, located in North Lab 1.701, is fully equipped to fabricate components and samples for lab courses and student senior design projects. It also provides manufacturing support for research conducted by graduate students and other researchers.